LinuxCNC and its competition-crushing features

There are hundreds of different control software for CNC milling machines and lathes, but one stands out in particular. We will cover why that is and how LinuxCNC has developed over time in this article.

History

LinuxCNC - previously called EMC, an abbreviation for "enhanced motion controller" is a software based on the development of NIST, the National Institute of Standards and Technology. These are guys that are big players in high-tech industries, so you can be sure their development isn't just a 14-year olds holiday project. The project, which was sponsored by the U.S. Air Force, among others, was used to control drives of all kinds. In the year 2000, there were some license changes, which led to the project becoming an open-source development.

The constant further development by a huge community led to the LinuxCNC we know today - a program that can be used to control milling machines, lathes, 3D printers, packing machines, and pretty much any other machine with motors.

How it works

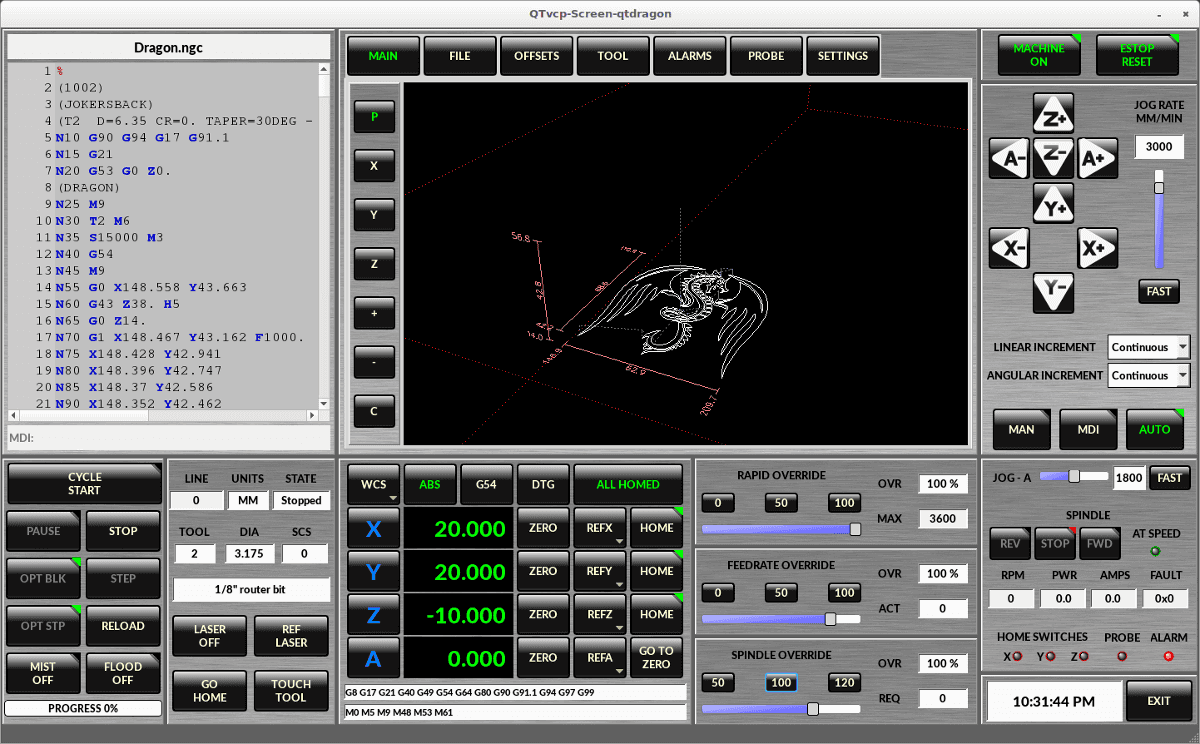

LinuxCNC runs on a standard PC under the Linux operating system with real-time functionality. It consists of several modules such as a GCode interpreter, various customizable user interfaces, a soft PLC, and much more.

For example, retrofits of milling machines including tool changers and custom gearbox control can be realized in the same way as 3D printers with their own user interface.

There are various options already implemented for controlling output cards, such as PCI, Ethernet, USB, or EtherCat. However, if you need a new technology not yet implemented, you can probably find a developer who is willing to help you.

Real-time capability

Real-time capability is a strong criterion when deciding in favor of LinuxCNC.

For the average user, Linux is usually more complicated to operate than Windows, for example. However, this inconvenience also comes with a lot of freedom, because everything can be customized. This means that a real-time environment is not a problem and not only private but also commercial projects in industry can be realized.

Open Source

Due to the open-source nature of the software, it is constantly being further developed and new features added. At the time of writing, almost 250 people have contributed to the development in the Github Repository of LinuxCNC.

If you need changes to a closed-source controller, you have to contact the manufacturer and possibly wait a long time or pay a lot of money. If the company no longer exists after 10 years, but old controllers cause problems, the only way out is often to switch to another manufacturer.

This is different with open-source projects. Even if you cannot program yourself, you'll always be able to find a programmer who can implement your wishes, as the source code is openly accessible to everyone. The fact that you are operating on the free market and are not dependent on a manufacturer means that prices are often much more competitive.

Conclusion

The possibilities of LinuxCNC are endless - but this can also be overwhelming for the inexperienced user. If you are looking for a control program that can be connected to your milling machine in a plug-and-play manner and works directly, LinuxCNC is the wrong choice.

However, if you are looking for an infinitely expandable and very reliable control system that can easily keep up with industrial manufacturers, LinuxCNC is the right choice. All this for the price that you have to put some work into configuration and setup.